Backward Inclined Centrifugal Fan | Centrifugal Blower Fan Price - AMX

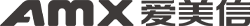

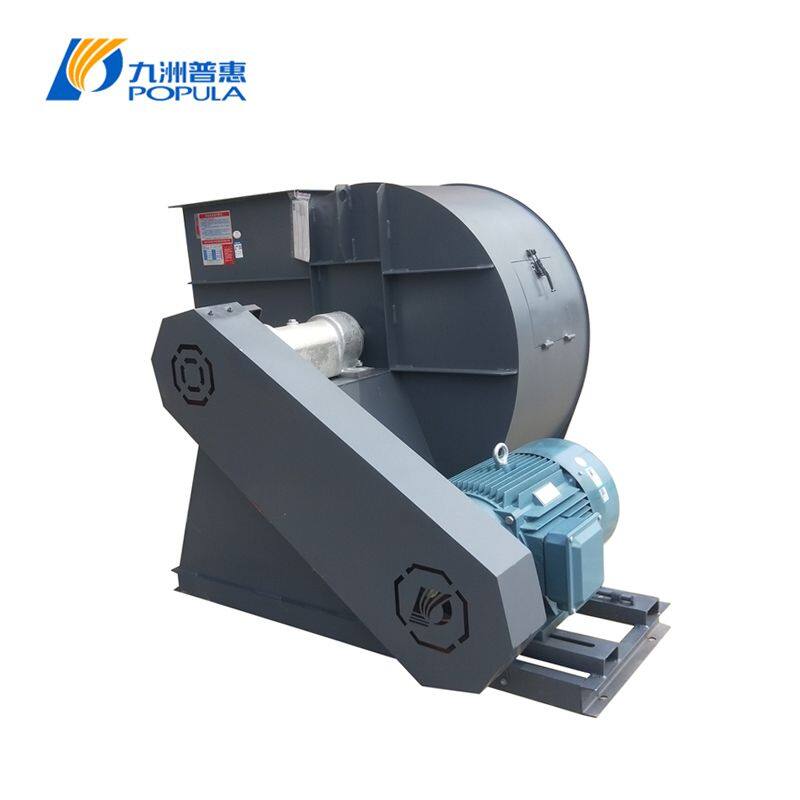

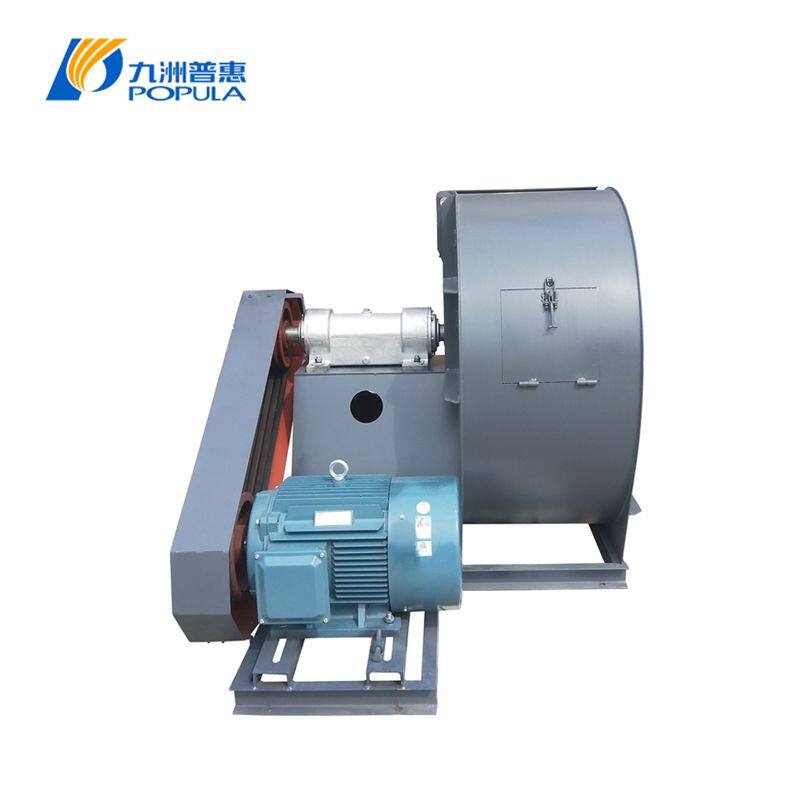

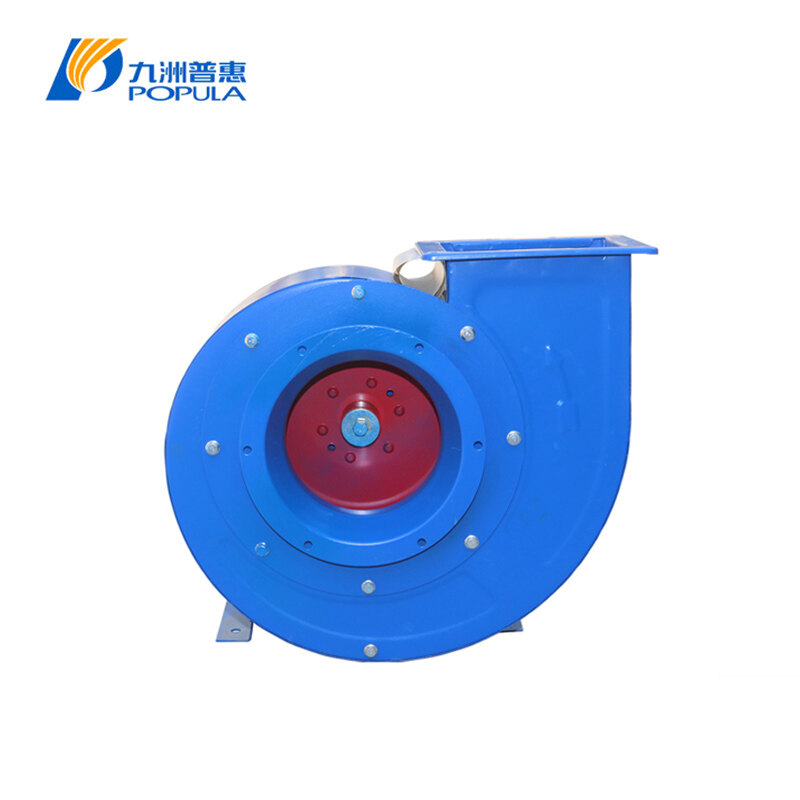

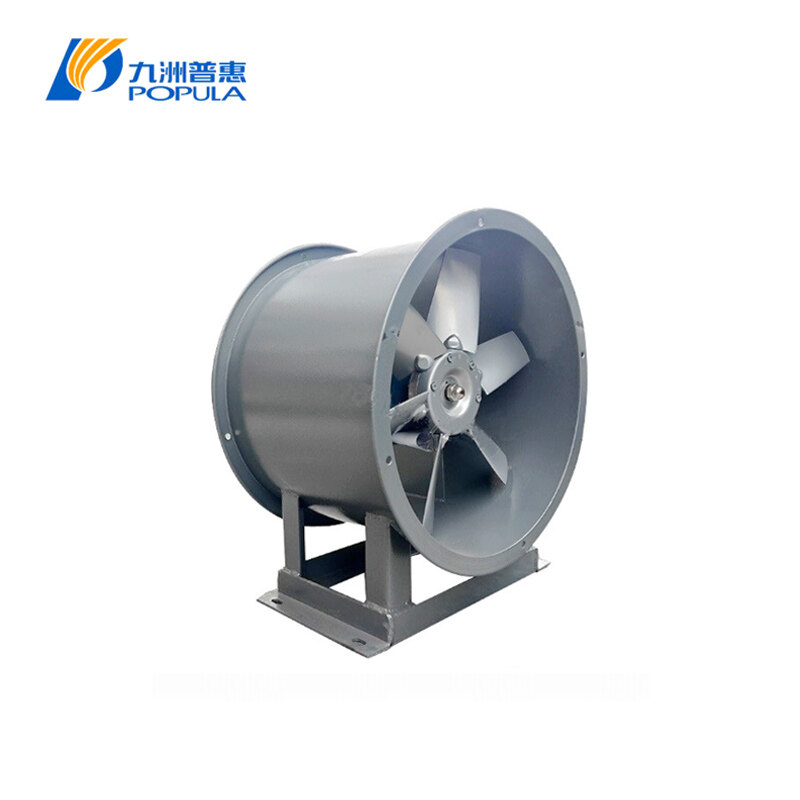

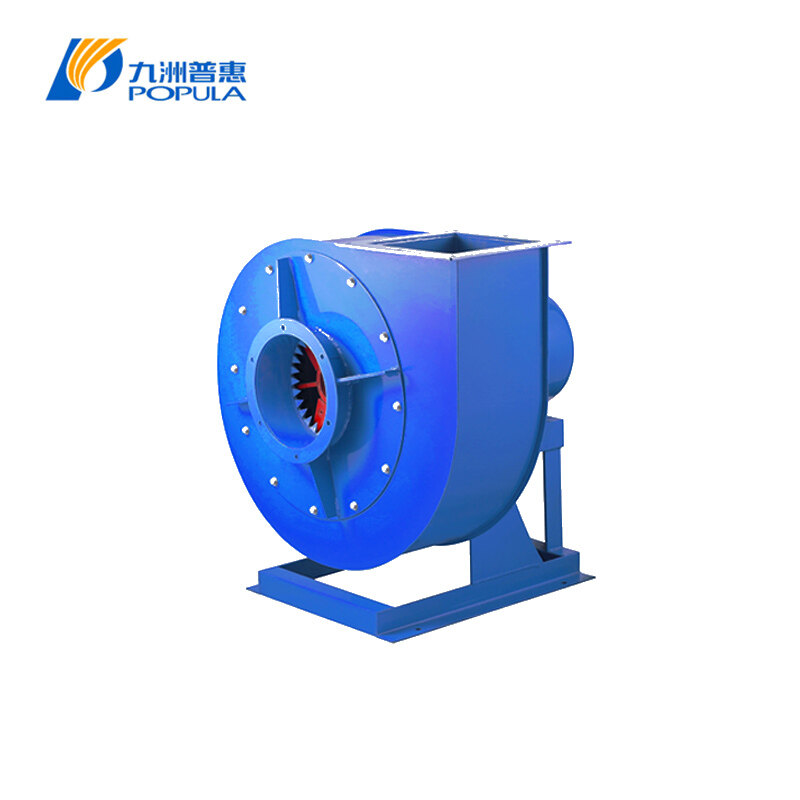

4-72-C Model Features:

Material Properties

4-72-C type backward inclined centrifugal fan is designed to fit the equipment of heavy industries, which can burn any kind of coal base, and is equipped with smoke and dust-removal device. It is applicable as long as the air volume and the performance fit the condition. However, the highest temperature shall not exceed 130℃. Our company can provide the stainless steel heat boiler centrifugal fan when the temperature of air must exceed 130℃. It can be used on many occasions to transfer materials and ventilation and improve motivation to systems.

Selection

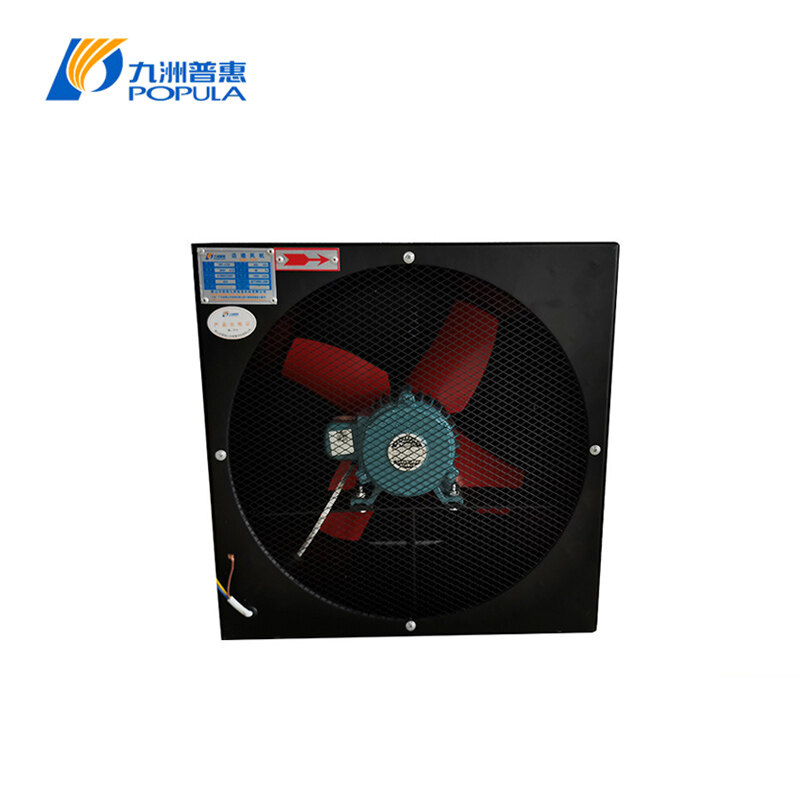

The backward inclined centrifugal fan has a single inlet, model No. Has No6,7,8,10,12,14,16, these kinds.

The centrifugal fan can be made into two forms: left-hand rotated and right-hand rotated. Face the fan from one end of the drive set. If the impeller rotates clockwise, we called it right-hand rotated, in short we use “right” for expression. If the impeller rotates anticlockwise, we call it left-hand rotated; in short, we use “left” for expression.

The position of the fan's air outlet is indicated by the angle of the air outlet of the housing. “left” and “right” can be made into 0°,90°, 180 °, or three angles.

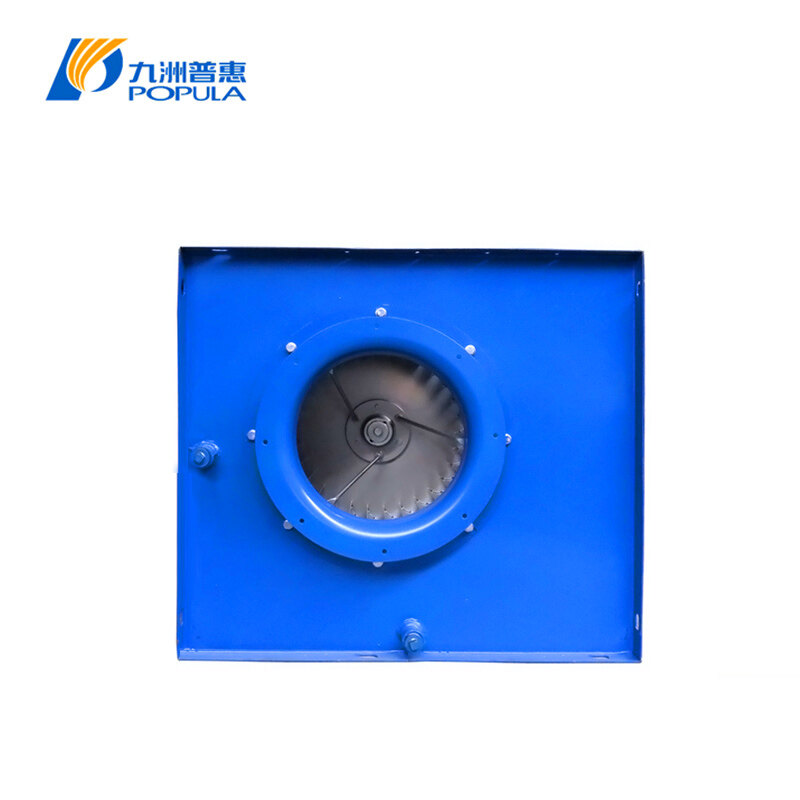

Fan Structure

The boiler centrifugal fan is made of the impeller, housing, air inlet, driven set, regulating door, and other parts.

The impeller has 12 backward inclined plate blades of 16Mn material, which are welded in the arc cone impeller cover and in the middle of the plate-shaped disc and are corrected by dynamic balance. Therefore, it runs smoothly, has high strength and wear resistance, and has a long service life.

| Model | Power (KW-P) |

RPM (r/min) |

Air Volume(m³/h) | Pressure(Pa ) |

| 6C | 15-4P | 2240 | 10314~20628 | 2734~1733 |

| 11-4P | 2000 | 9209~18418 | 2176~1380 | |

| 7.5-4P | 1800 | 8288~16576 | 1760~1116 | |

| 5.5-4P | 1600 | 7367~14734 | 1389~881 | |

| 3-4P | 1250 | 5756~11511 | 846~537 | |

| 2.2-4P | 1000 | 4605~9209 | 541~344 | |

| 1.1-4P | 800 | 3684~7367 | 346~220 | |

| 7C | 18.5-4P | 1800 | 13161~26322 | 2395~1519 |

| 15-4P | 1600 | 11698~23397 | 1890~1199 | |

| 11-4P | 1450 | 10602~21204 | 1553~984 | |

| 7.5-4P | 1250 | 9140~18279 | 1151~731 | |

| 5.5-4P | 1120 | 8189~16378 | 924~586 | |

| 4-4P | 1000 | 7312~14623 | 736~468 | |

| 8C | 37-4P | 1800 | 28105~36427 | 2920~2302 |

| 30-4P | 1800 | 19646~25240 | 3143~3032 | |

| 22-4P | 1600 | 17463~22435 | 2478~2390 | |

| 11-4P | 1250 | 13643~25297 | 1507~1106 | |

| 7.5-4P | 1120 | 12224~15705 | 1209~1166 | |

| 5.5-4P | 1000 | 10914~14022 | 963~929 | |

| 5.5-4P | 900 | 14052~18213 | 725~572 | |

| 3-4P | 800 | 8732~16190 | 615~452 | |

| 2.2-4P | 710 | 7749~11085 | 485~450 | |

| 10C | 37-4P | 1250 | 34863~48797 | 2373~1877 |

| 30-4P | 1120 | 31237~43722 | 1902~1505 | |

| 18.5-4P | 1000 | 27890~39038 | 1514~1199 | |

| 15-4P | 900 | 25101~35134 | 1225~970 | |

| 11-4P | 800 | 22312~31230 | 967~766 | |

| 7.5-4P | 710 | 19802~27717 | 761~603 | |

| 5.5-4P | 630 | 17571~24594 | 599~475 | |

| 12C | 75-4P | 1120 | 53978~75552 | 2746~2172 |

| 55-4P | 1000 | 63953~67457 | 1859~1729 | |

| 37-4P | 900 | 43375~60712 | 1767~1399 | |

| 30-4P | 800 | 38556~53966 | 1395~1104 | |

| 18.5-4P | 710 | 34218~47895 | 1097~869 | |

| 15-4P | 630 | 30362~42498 | 863~684 | |

| 11-4P | 560 | 31774~37776 | 646~540 | |

| 7.5-4P | 500 | 24097~33728 | 543~430 | |

| 14C | 110-4P | 1000 | 76535~107124 | 2985~2361 |

| 75-4P | 900 | 68881~96412 | 2412~1908 | |

| 55-4P | 800 | 61228~85699 | 1903~1506 | |

| 37-4P | 710 | 54340~76058 | 1497~1185 | |

| 30-4P | 630 | 48217~67488 | 1177~932 | |

| 18.5-4P | 560 | 42859~59990 | 929~736 | |

| 15-6P | 500 | 38267~53562 | 741~587 | |

| 11-6P | 450 | 34441~48206 | 599~474 | |

| 7.5-6P | 400 | 30614~42850 | 474~375 | |

| 5.5-6P | 355 | 27170~38029 | 372~295 |