Laser engraving is a precise and intricate process used in various industries to create detailed designs on different materials. However, this process generates fumes, smoke, and particles that can compromise both the engraving quality and the work environment. To mitigate these issues, incorporating a laser engraver exhaust fan is crucial. This article explores the importance of exhaust fans in laser engraving, detailing their benefits, features, and maintenance.

Understanding Laser Engraver Exhaust Fans

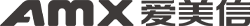

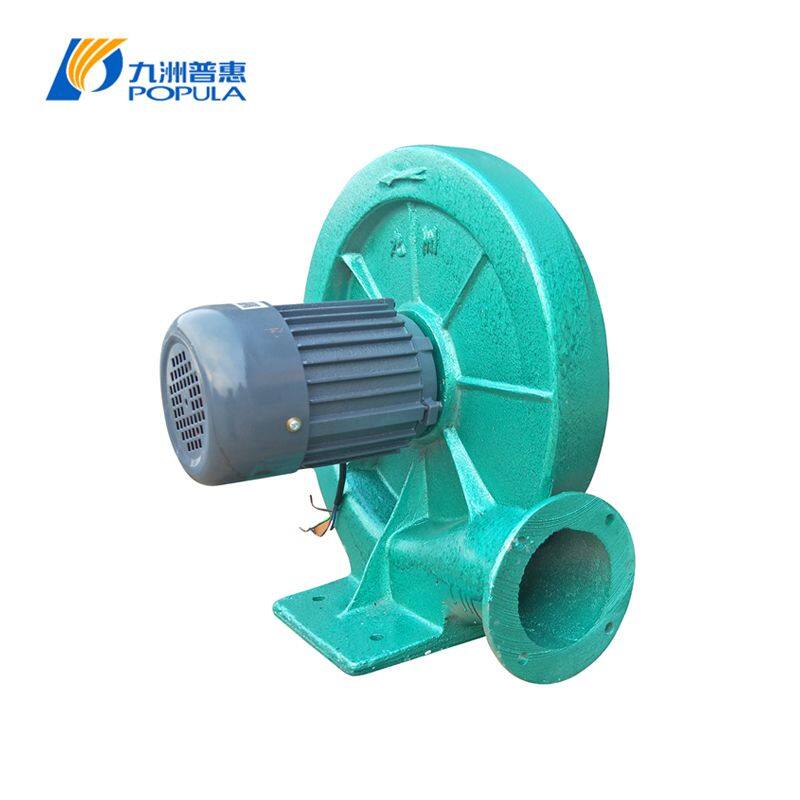

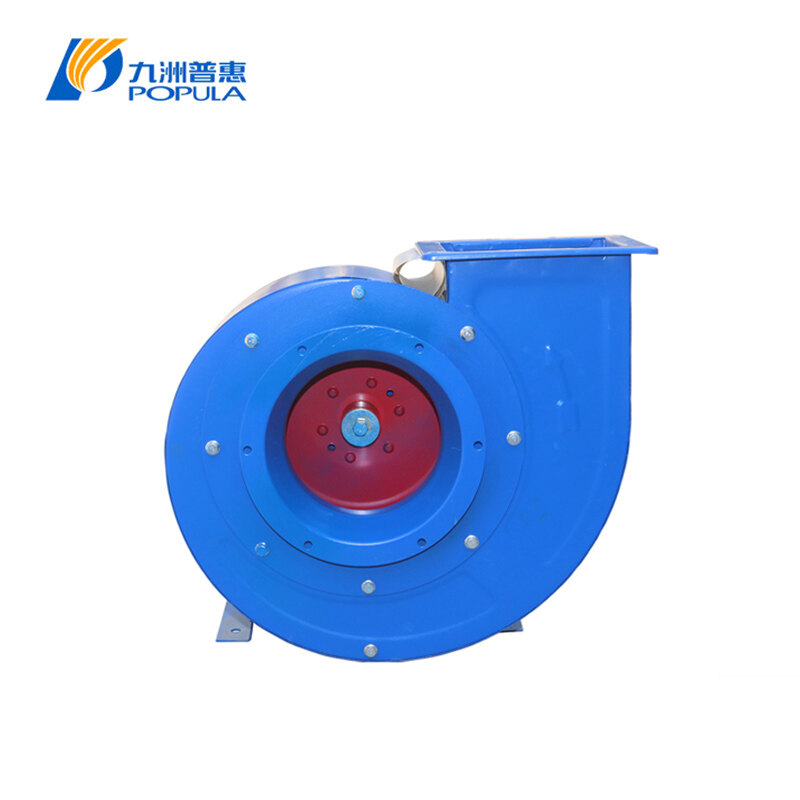

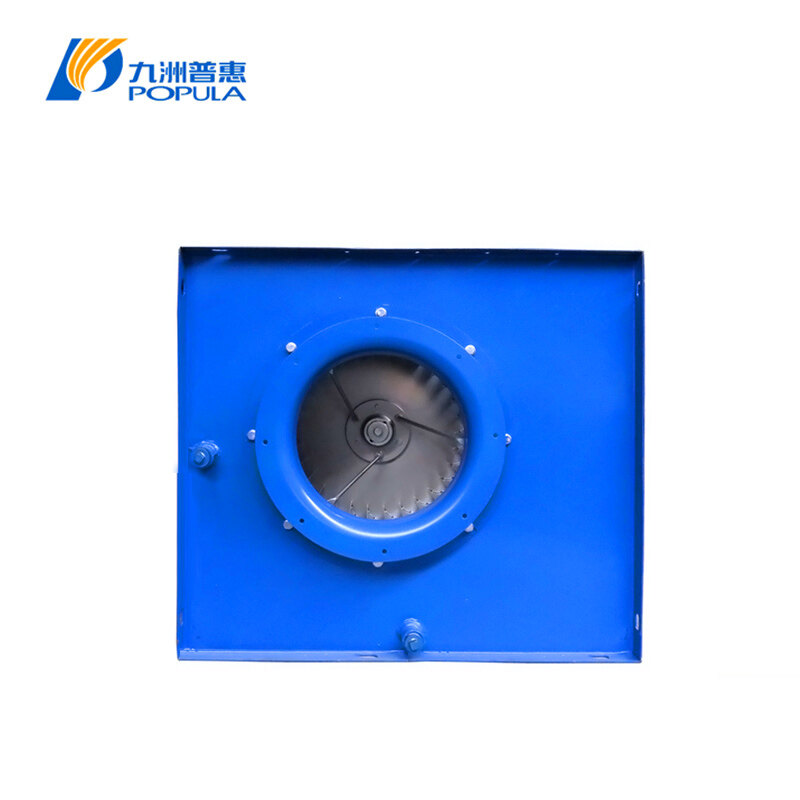

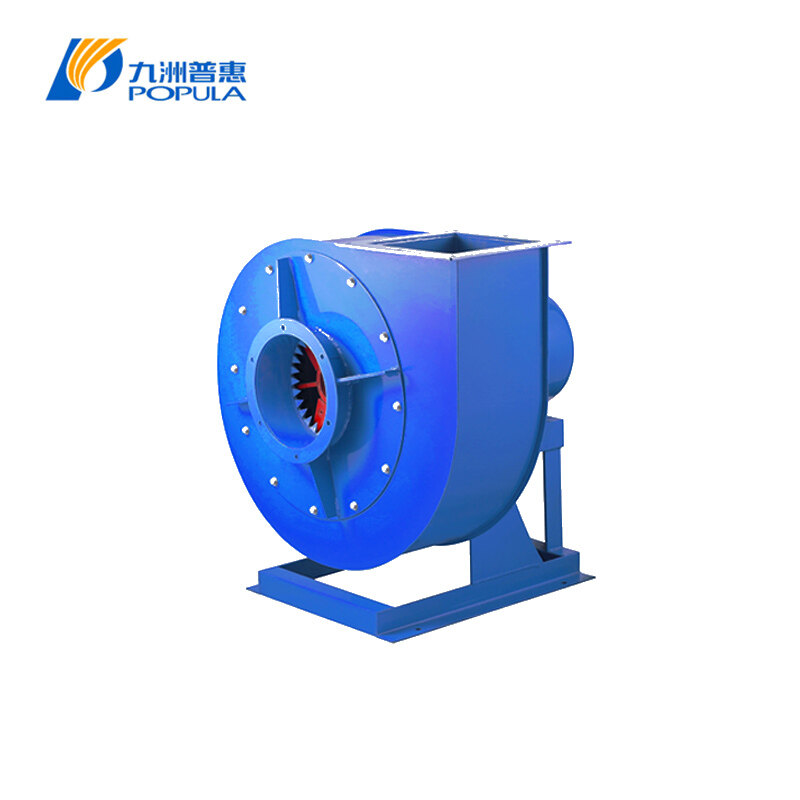

A laser engraver exhaust fan is a specialized device designed to remove fumes, smoke, and particles produced during the laser engraving process. These fans work by creating a vacuum that draws contaminated air away from the engraving area, filtering it to remove harmful substances before expelling clean air back into the environment. The core components of an exhaust fan system include the fan itself, ducting, and filtration units, which work together to ensure a clean and safe workspace.

Benefits of Using Exhaust Fans in Laser Engraving

Improved Air Quality: One of the primary benefits of using an exhaust fan is the significant improvement in air quality. Laser engraving releases various toxic fumes and particulates that can be hazardous to health. An exhaust fan effectively removes these contaminants, ensuring a safer working environment for operators.

Enhanced Engraving Precision: Contaminants like smoke and dust can interfere with the laser beam, affecting the precision of the engraving. By using an exhaust fan to remove these particles, the laser can operate more efficiently, resulting in cleaner and more accurate engravings.

Increased Equipment Lifespan: Accumulation of dust and debris can cause wear and tear on laser engraving equipment, leading to more frequent maintenance and reduced lifespan. An exhaust fan helps keep the machinery clean, reducing the risk of damage and prolonging the equipment's operational life.

Key Features to Look for in a Laser Engraver Exhaust Fan

Airflow Capacity: The efficiency of an exhaust fan is largely determined by its airflow capacity, measured in cubic feet per minute (CFM). A higher CFM rating indicates better performance in removing contaminants. It is essential to choose a fan with adequate capacity to handle the volume of fumes produced by your laser engraver.

Noise Level: Operating noise is another critical factor. A quieter exhaust fan contributes to a more comfortable working environment. Look for models that offer a good balance between power and noise reduction features.

Filter Quality: High-quality filters are essential for effectively capturing harmful particles. HEPA filters, in particular, are known for their ability to trap fine particles, ensuring that the expelled air is clean. Regularly replacing these filters is crucial for maintaining optimal performance.

Installation and Maintenance Tips

Proper Installation Guidelines: Correct installation of the exhaust fan is vital for its effectiveness. Ensure that the fan is appropriately sized for your laser engraver and that the ducting is correctly configured to maximize airflow. Position the exhaust outlet in a location where the expelled air will not re-enter the workspace.

Regular Maintenance Practices: To keep the exhaust fan functioning efficiently, regular maintenance is necessary. This includes cleaning or replacing filters as recommended by the manufacturer, checking for blockages in the ducting, and ensuring the fan blades are free of dust and debris.

Troubleshooting Common Issues: Common issues such as reduced airflow, unusual noises, or frequent filter clogging can be addressed by inspecting the system for leaks, ensuring the ducting is secure, and replacing worn-out components. Keeping a maintenance log can help track and predict when parts need attention.

Conclusion

Investing in a high-quality laser engraver exhaust fan is essential for anyone involved in laser engraving. The benefits, from improved air quality and enhanced precision to increased equipment lifespan, make it a valuable addition to your workspace. By understanding the key features to look for and maintaining the system properly, you can ensure a safe and efficient engraving process. Prioritize a good exhaust fan to protect your health, enhance your work, and prolong your equipment's life.