The ventilation system fan is highly utilized in industrial and commercial applications, such as duct exhaust, ventilation, heat exhaust, cooling, and so on. In fact, there is no clear definition of the term "industrial fan." As we all know, axial fans and centrifugal fans are the two main popular types of industrial fans. This article discusses the difference between centrifugal and axial fans.

What is the centrifugal blower?

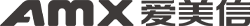

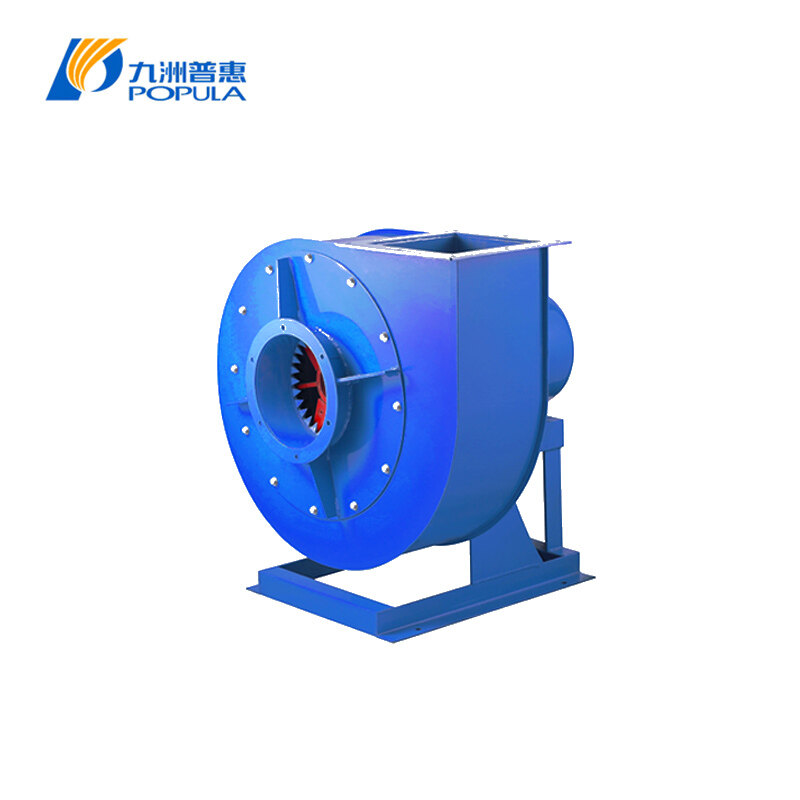

Centrifugal blower: The centrifugal blower, also known as the centrifugal fan, consists of a motor-driven hub and a fan wheel – a series of blades mounted on the circular hub.

The fan wheel increases the pressure of the incoming airflow, and the centrifugal blower transfers high-pressure air in a radial direction - the direction of the outward flowing air is changed, usually at a 90-degree angle to the air intake, means the air is exhausted in a vertical manner.

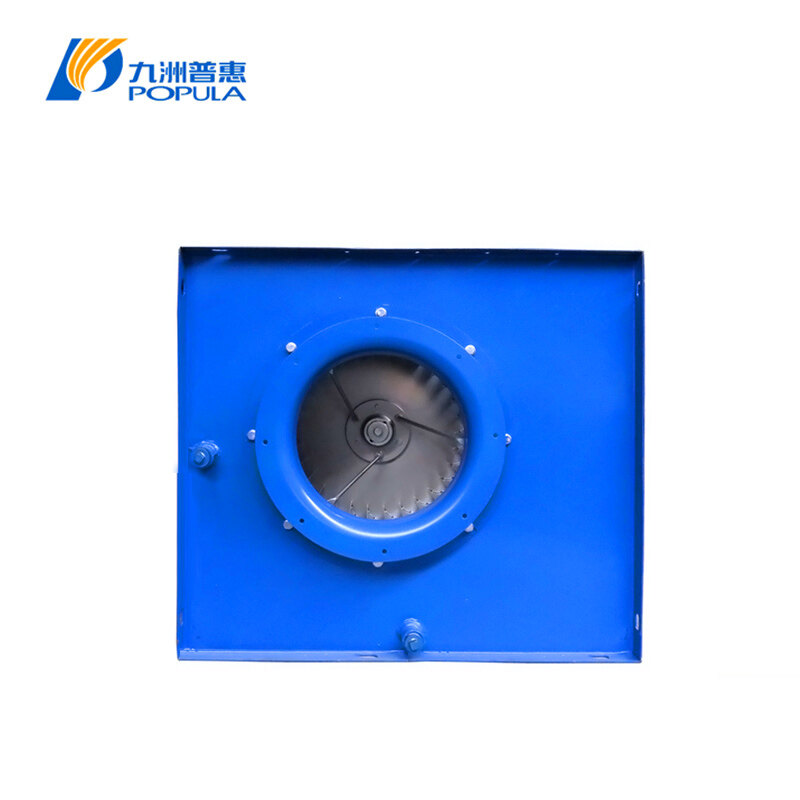

industrial centrifugal blower fans

What is the axial fan?

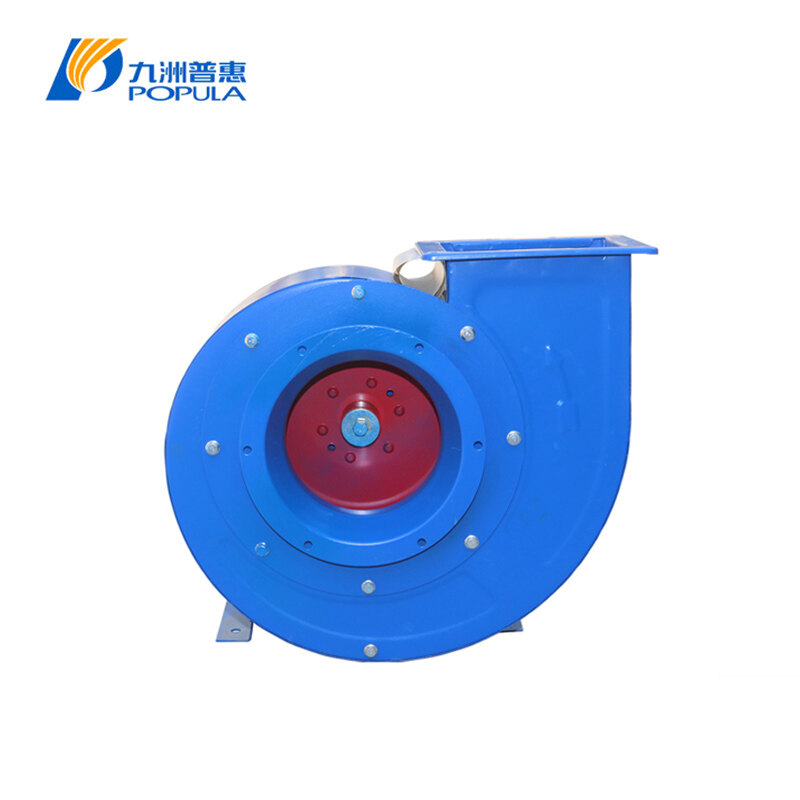

Axial fan: The axial fan has a motor-driven rotating shaft (axis) on which are mounted angled blades, rotating around and drawing air in parallel to that axis to force air out in the same direction.

In other words, the axial fan creates airflow in the direction of the axis. That's why it was named axial fan. Axial fans are sometimes referred to as propeller fans. You may also hear other terms for tube-shaft or bladed axial fans, usually referring to axial fans installed in ducts.

What are the main applications of the industrial centrifugal blower fan?

Centrifugal fans primarily pressurize the air inside the blower housing, and the airflow is then directed through ducts or pipes to produce a more consistent, high pressure but a lower flow rate airflow than axial fans.

Industrial centrifugal blowers can be equipped with forwarding or backward curved impellers for blowing or suction. It also requires a higher power input to provide a more consistent high-pressure airflow than an axial fan.

The combination of high pressure and low air volume delivery makes centrifugal fans ideal for moving air through concentrated areas such as ductwork, piping for exhaust, ventilation, and more.

With excellent reliability and durability, the dust removal centrifugal fan operates well in many applications, such as some harsh and dirty environments with particulates, hot air, gases, etc.

The cabinet type centrifugal fan is also often used with ducted systems or piping because the air can exit the inlet at a 90-degree angle for greater directionality, ideal for air conditioning or drying systems, even in smaller classes of mechanical systems.

What are the common uses of high efficiency axial fan?

The axial fan moves large volumes of air effectively and efficiently, providing large volumes of low pressure airflow, often used to cool objects or ventilate spaces.

This combination of low pressure and high flow airflow is ideal for cooling equipment and spaces of any size, as the airflow of axial flow fan working is evenly distributed over a defined area. And they do not require a lot of power to operate, depending on the size. Of course, axial fans can also operate as exhaust fans.

Thus, from a functional point of view, axial fans replace centrifugal blowers in certain applications. The high efficiency axial fan is ideal for cooling electronic equipment or computer rooms, HVAC operations, AC condensers, heat exchange units, or spot cooling in industrial systems.

Is an axial or centrifugal fan better?

Here is a quick query about centrifugal blower vs axial fan, and you can come up with the answer simply and intuitively with the following table: which one is better for your actual needs.

| Centrifugal Fans | Axis fans |

|---|---|

| High Volume/Low Pressure | High Pressure/Low Volume |

| Airflow parallel to the axis | Airflow perpendicular to the axis |

| Higher operating speed than centrifugal | Lower operating speed than axial |

| Compact designs | Better for specifically directed cooling |

| Lower power usage than centrifugal | Typically uses more power than axial |

| Less audible noise than centrifugal | More audible noise than axial |

| Typically, less expensive than centrifugal | Durable and resistant to harsh environments |

Conclusion

Both centrifugal blower and axial flow fan have their own advantages and disadvantages. If you are still having trouble deciding which one is better, please feel free to contact us at Billy@populafan.com.

AMX is one of the leading centrifugal fan blower manufacturers as well as industrial axial fans manufacturers in China. We offer high-quality industrial centrifugal blower fans and large volume axial fans at affordable prices!