In the fast-paced realm of industrial operations, where precision and reliability are paramount, maintaining optimal conditions is not just a consideration; it's a fundamental necessity. This article delves into the critical role played by cabinet ventilation fans, exploring how these essential components contribute to the seamless functioning of electronic equipment within industrial environments.

Understanding Cabinet Ventilation Fans

Core Functions and Mechanisms

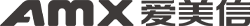

Cabinet ventilation fans operate as guardians of temperature regulation within enclosures housing electronic components. Their mechanism is grounded in simplicity yet critical functionality. By facilitating a continuous flow of air, these fans prevent the accumulation of heat, ensuring a stable environment for sensitive devices to operate optimally.

Types of Cabinet Ventilation Fans

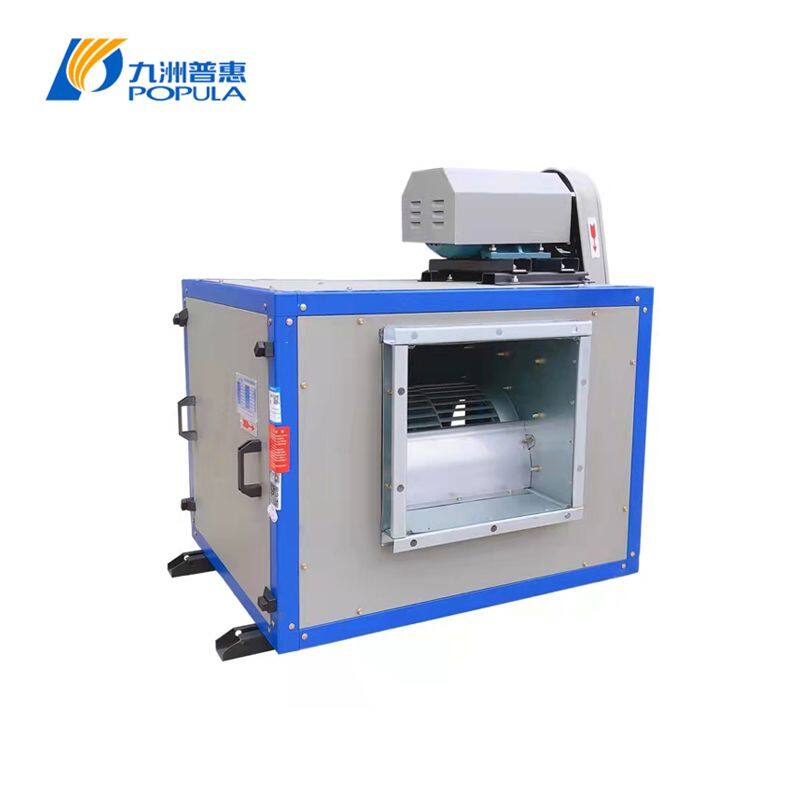

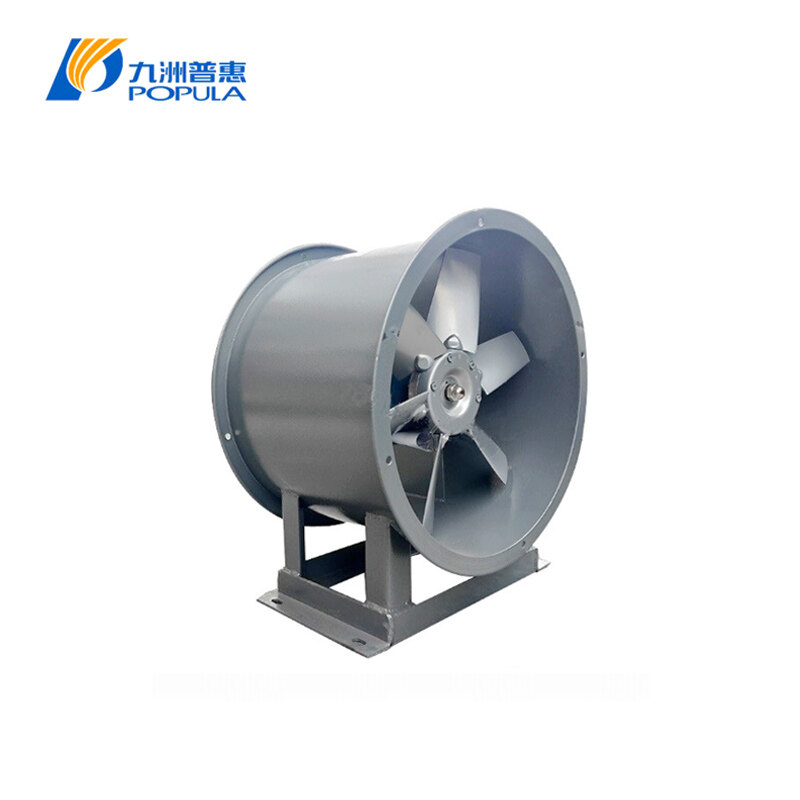

Axial Fans: Axial fans, recognized for their efficiency, move air parallel to the fan's axis, creating a consistent and uniform airflow within enclosures. Their versatility makes them suitable for a range of general cooling purposes.

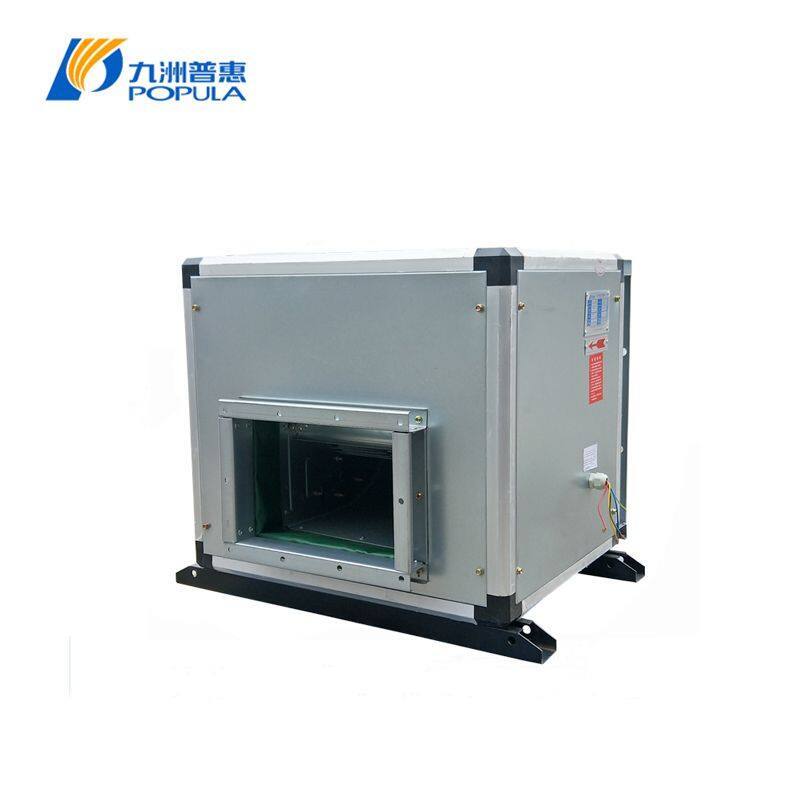

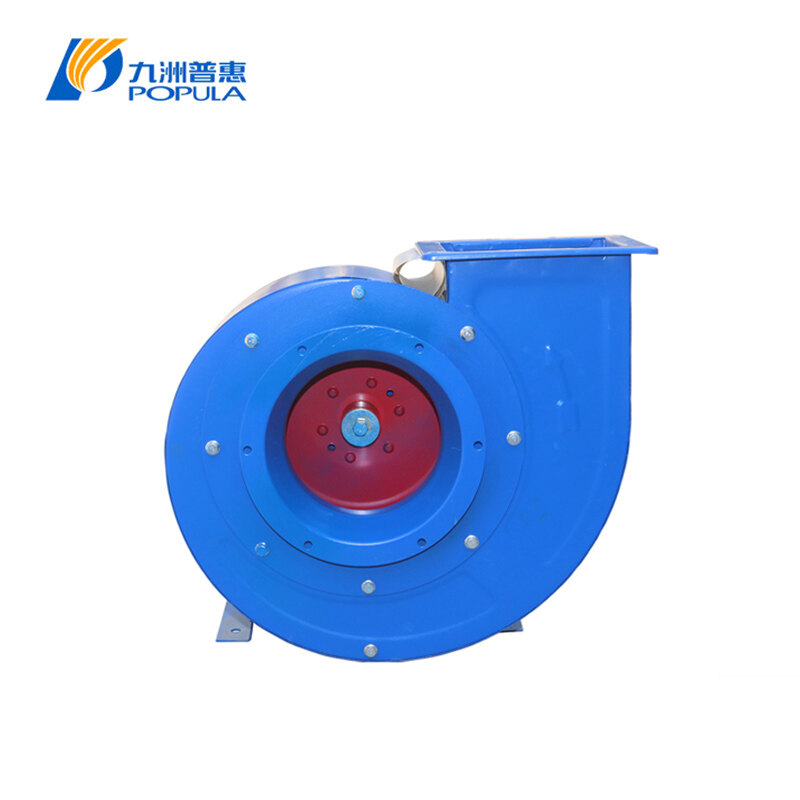

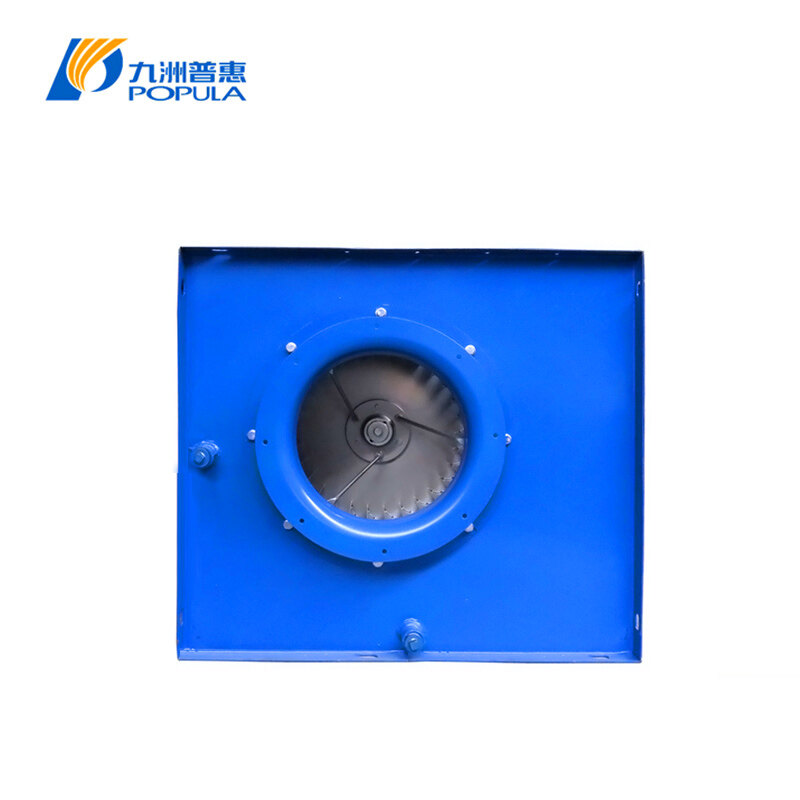

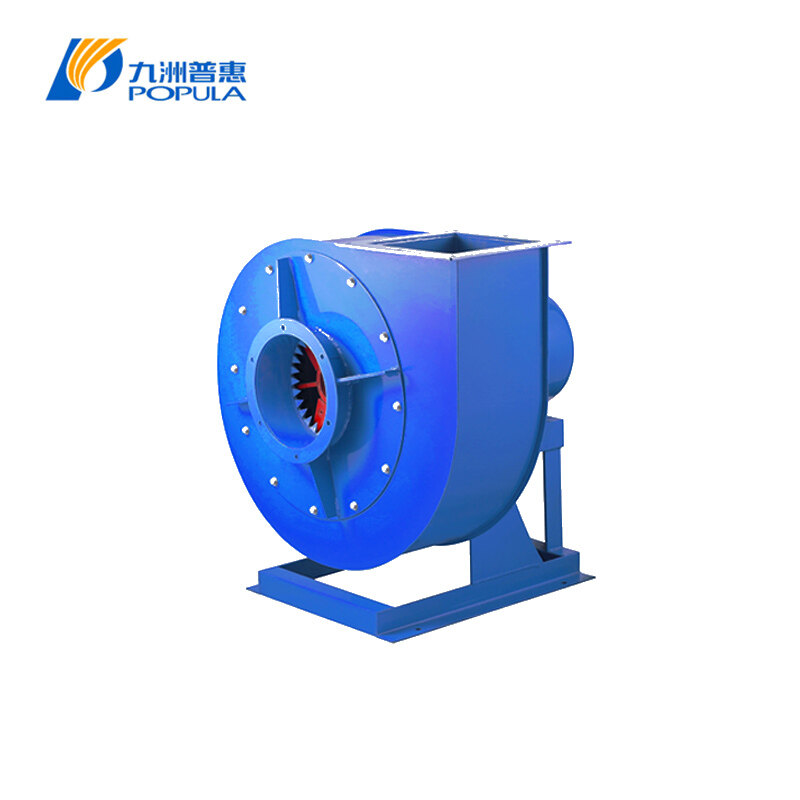

Centrifugal Fans: Operating with a dynamic approach, centrifugal fans pull air into the center of the fan and redirect it perpendicular to the fan's axis. This design proves advantageous in scenarios where increased pressure is required, making them ideal for specific industrial applications.

Benefits of Cabinet Ventilation Fans

Temperature Regulation for Sensitive Equipment

The primary advantage of cabinet ventilation fans lies in their ability to maintain an optimal operating temperature for electronic components. This proactive approach mitigates the risk of overheating, ensuring machinery operates reliably within recommended temperature thresholds.

Prevention of Heat-Related Damage

Uncontrolled heat buildup poses a significant threat to electronic components, potentially leading to irreversible damage. Cabinet ventilation fans act as a preventive measure, creating a stable environment that protects against potential thermal damage, thereby preserving the integrity of critical equipment.

Prolonged Lifespan of Electronic Components

Cooler operating temperatures directly contribute to the longevity of electronic components. Cabinet ventilation fans play a crucial role in safeguarding the initial investment by reducing the frequency of replacements, translating to long-term cost savings.

Choosing the Right Cabinet Ventilation Fan

Evaluating Size and Capacity

The meticulous selection of a cabinet ventilation fan involves evaluating size and capacity. Understanding the heat dissipation requirements of enclosed equipment ensures that the chosen fan can effectively manage the thermal load without compromising efficiency.

Noise Levels and Operational Considerations

Functionality is paramount, but so is the consideration of noise levels. Achieving a balance between efficient cooling and minimal operational noise is crucial for creating a conducive working environment where precision and tranquility coexist seamlessly.

Energy Efficiency and Sustainability

In an era emphasizing sustainability, opting for energy-efficient cabinet ventilation fans aligns with environmental goals. These fans not only reduce energy consumption but also contribute to an organization's commitment to eco-friendly practices, demonstrating a commitment to responsible industrial practices.

Big Air Volume Cabinet Centrifugal Fan

Installation and Maintenance Best Practices

Proper Placement for Optimal Airflow

Effective cabinet ventilation necessitates strategic fan placement within the enclosure. Ensuring unobstructed airflow around electronic components is essential for efficient cooling and optimal performance. Thoughtful placement aligns with a professional approach to maximizing the benefits of ventilation systems.

Regular Cleaning and Inspection

Maintenance is paramount for sustained performance. Regular cleaning and inspection of fans and their components prevent dust accumulation, ensuring that the fans operate at peak efficiency. This disciplined approach to maintenance underscores a commitment to reliability and operational excellence.

Troubleshooting Common Issues

Understanding potential issues, such as fan malfunctions or inadequate airflow, is crucial for prompt resolution. A proactive approach to troubleshooting minimizes downtime and ensures swift resolution of operational challenges, emphasizing a dedication to continuous improvement and seamless operations.

Conclusion

The incorporation of cabinet ventilation fans is a strategic investment for businesses aiming to optimize industrial operations. These fans, with their functional prowess, contribute silently yet significantly to the seamless functioning of electronic machinery, ensuring a harmonious and efficient workplace. As organizations navigate the complexities of modern industry, prioritizing professional ventilation solutions becomes the key to operational excellence.